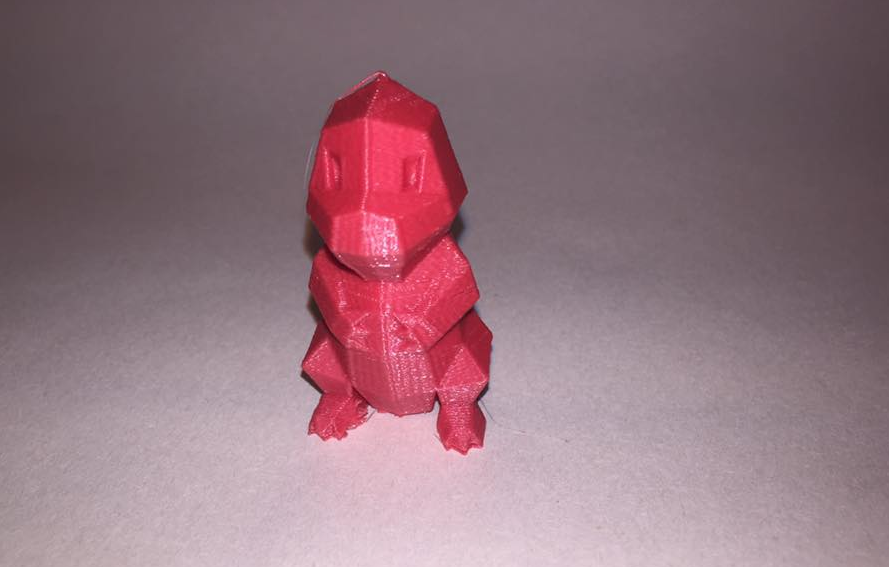

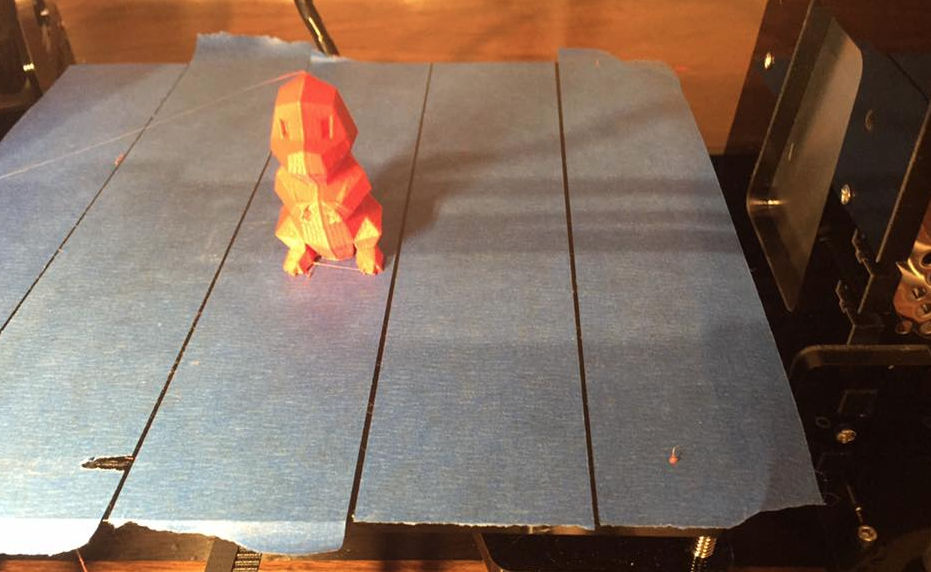

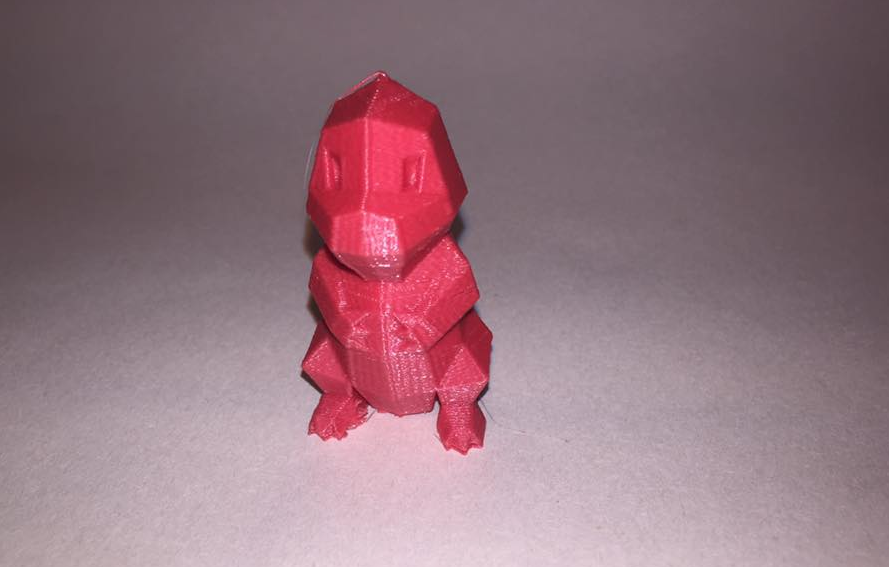

Terry and Claire’s new printer is working! Terry writes:

Hi Matt.

3D printing steward, CAD geek, software engineer, and technological history buff.

Terry and Claire’s new printer is working! Terry writes:

Hi Matt.

At our 3D print meeting on May 16, a few of us discussed modeling for 3D printing. We used Jill’s thermos stopper as an example to be reproduced using Fusion 360. The original stopper was made of formed stainless steel (I think), and had shallow external threads extending about 1 1/4 turns. The thread cross-section was a graceful curve, making it easy to clean, and probably easy to manufacture.

Most of the modeling was straightforward, but the non-standard threads presented a challenge. This post makes good on my promise to follow-up on the subject. I’ll also take a few side trips to share some of my habits that I think make the modeling process easier. You’ll get more out of this post if you’re at least somewhat familiar with Fusion 360. Their website has excellent online tutorials.

Before continuing, I should point out that Fusion 360 does have a thread tool capable of creating a number of thread forms by simply entering measurements in a dialog box. It supports a lot of thread types and it’s definitely the way to go if you’re working with standard fasteners or if a standard thread form will do. For a model to be 3D printed complete with threads, be sure to check the modeled box. The threads will have to be fairly coarse to get reasonable results on our FDM printers. Un-modeled threads merely communicate the design intent to the manufacturing team. This saves a lot of space in the design file, allows for much faster rendering, and is appropriate when the threads will be cut by a tap or die as a secondary manufacturing step.

But on with our example. First off, we need something to apply the threads to, so I’ll take a detour to re-create the basic stopper model. In fact I’ll illustrate three different ways to do it. (I did not save the original model we worked on, so these dimensions are just the best I can remember.)

Stopper body, method 1

The first technique I’ll show is perhaps the most intuitive to a newcomer. Folks who’ve used Sketchup or another simple modeling tool may find this familiar.

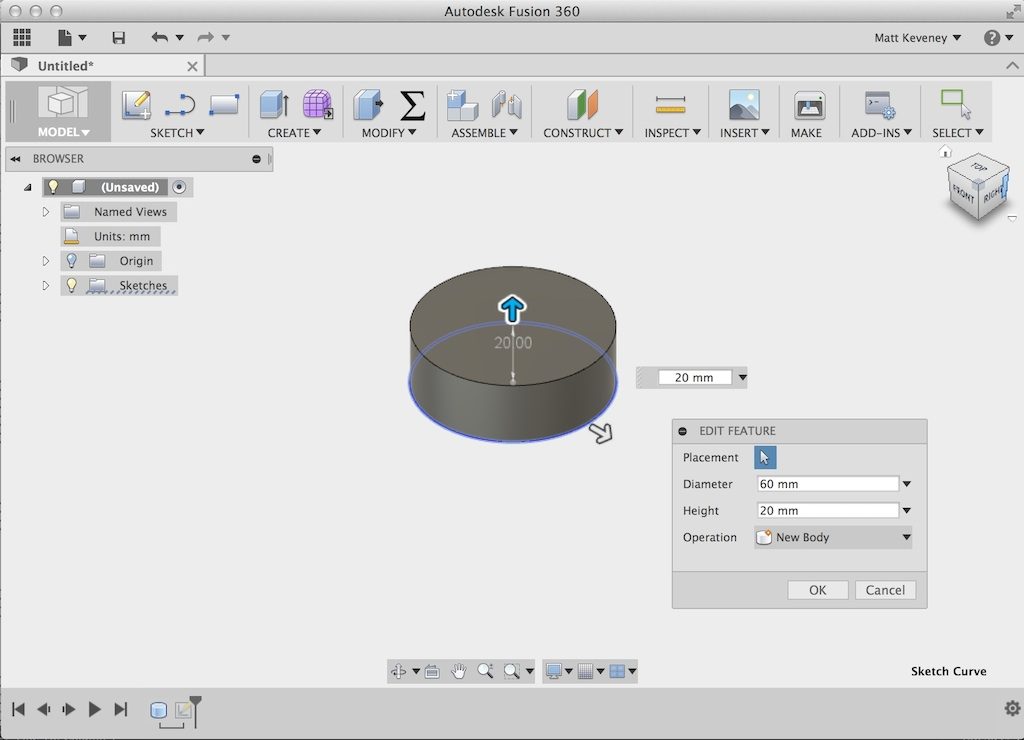

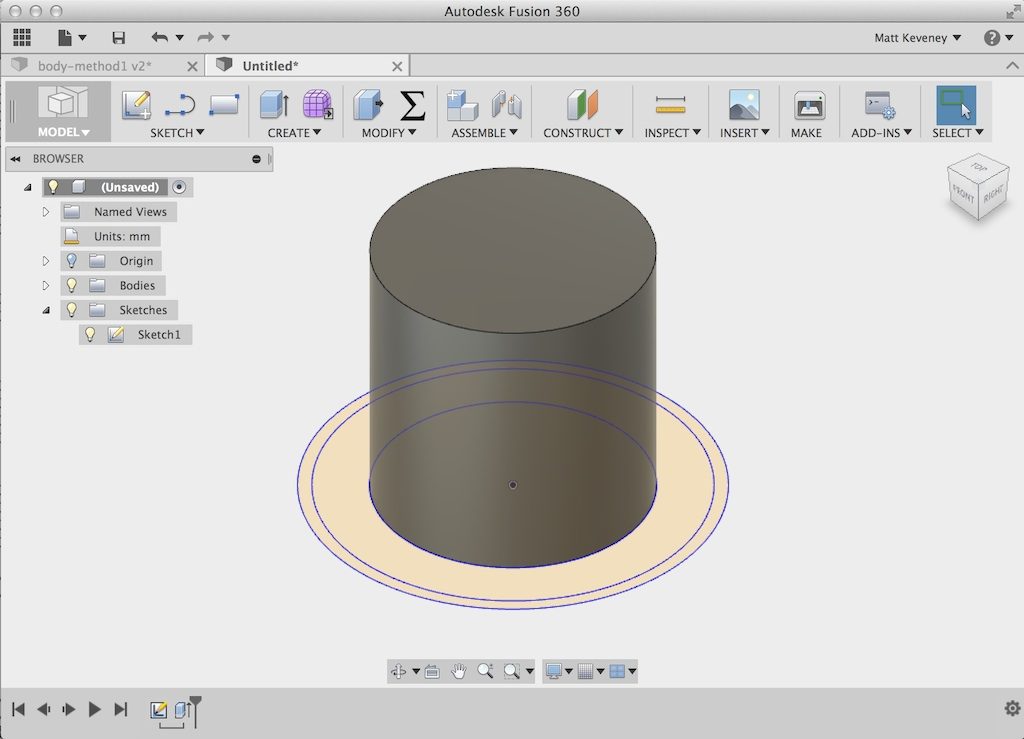

First create a cylinder, specifying the dimensions of the large end of the stopper.

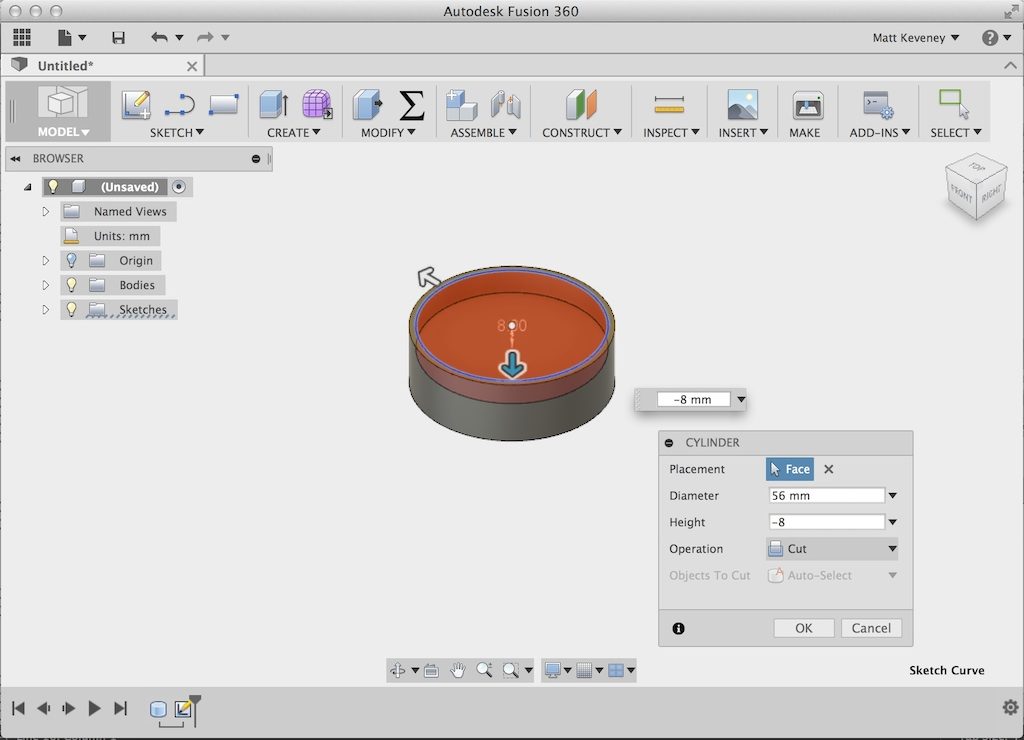

Then create another cylinder to the dimensions of the cutout portion where the gasket seats, and logically subtract it from the first part.

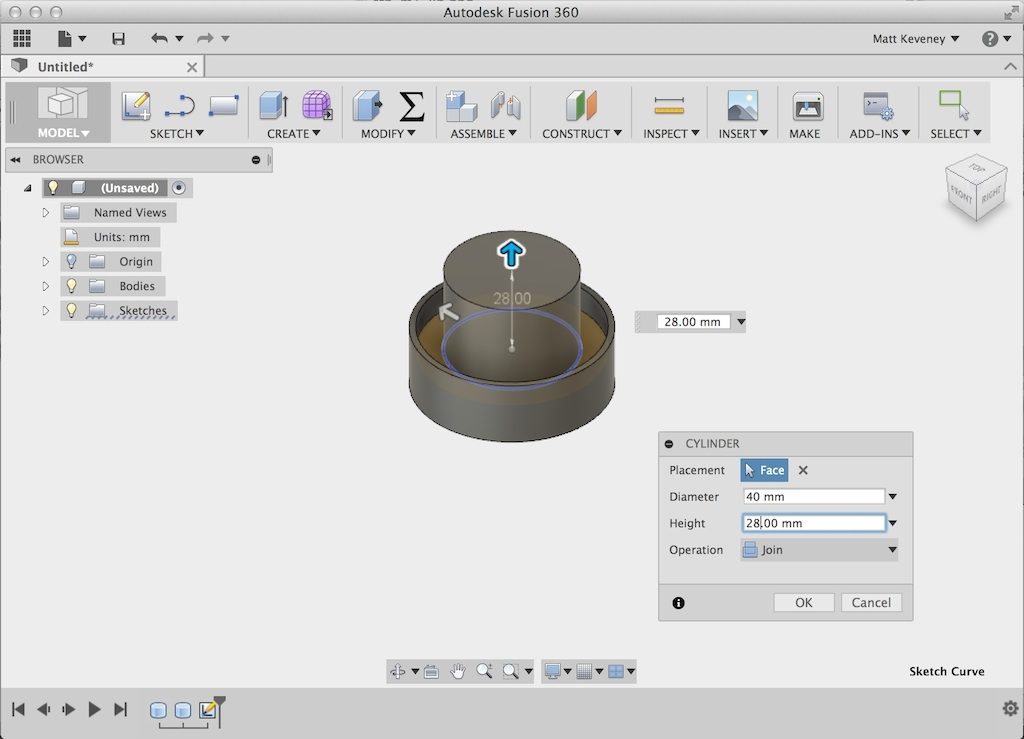

Finally, create a third cylinder, the dimensions of the inner portion of the stopper, and join it with the first body. Fusion 360 chooses join or cut operations by default if the new volume touches or intersects an existing body.

This is my least-favorite method of the three described here, since the dimensions are scattered among the operations. To make a change or even just view a measurement, we have to search through the operation history (at the bottom of the screen), opening the steps one-by-one. Still, the results are equivalent, so if it seems intuitive and comfortable to you, by all means use this technique.

Stopper body, method 2

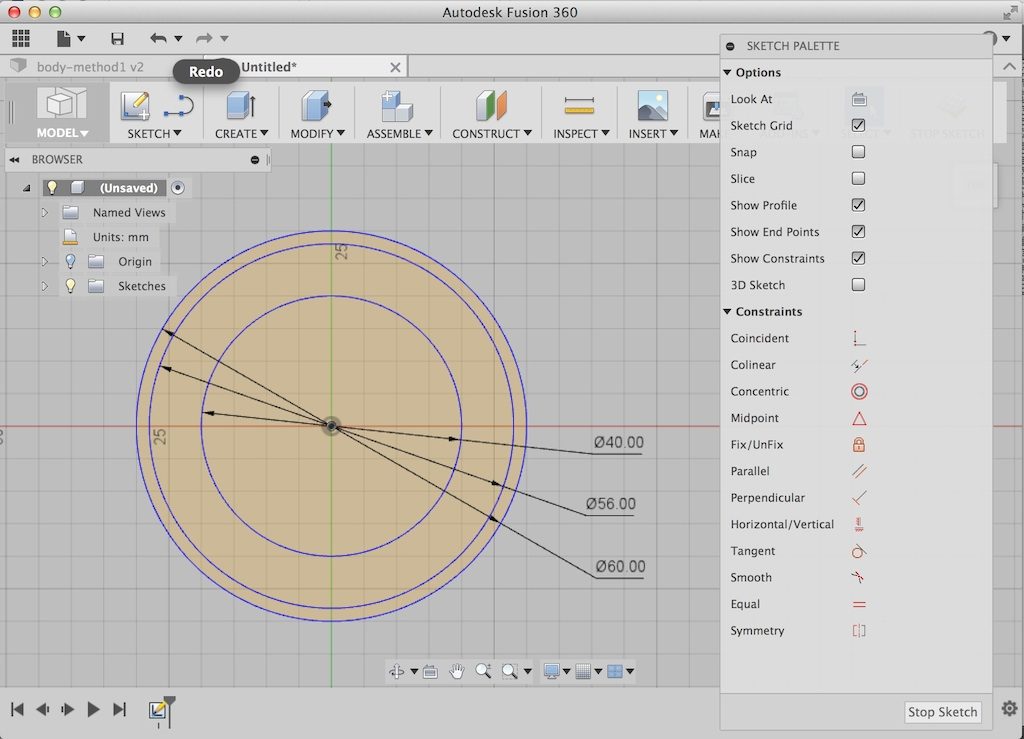

Start the next method with a sketch on the XZ plane containing 3 concentric circles. These are dimensioned to the diameter of each section. Fusion 360 by default arranges positive Y up, positive Z toward you. Most 3D printers consider the bed to be the XY plane, with Z being the vertical axis. This is not a big deal, since we can rotate our part before slicing, but it might be confusing to a newcomer.

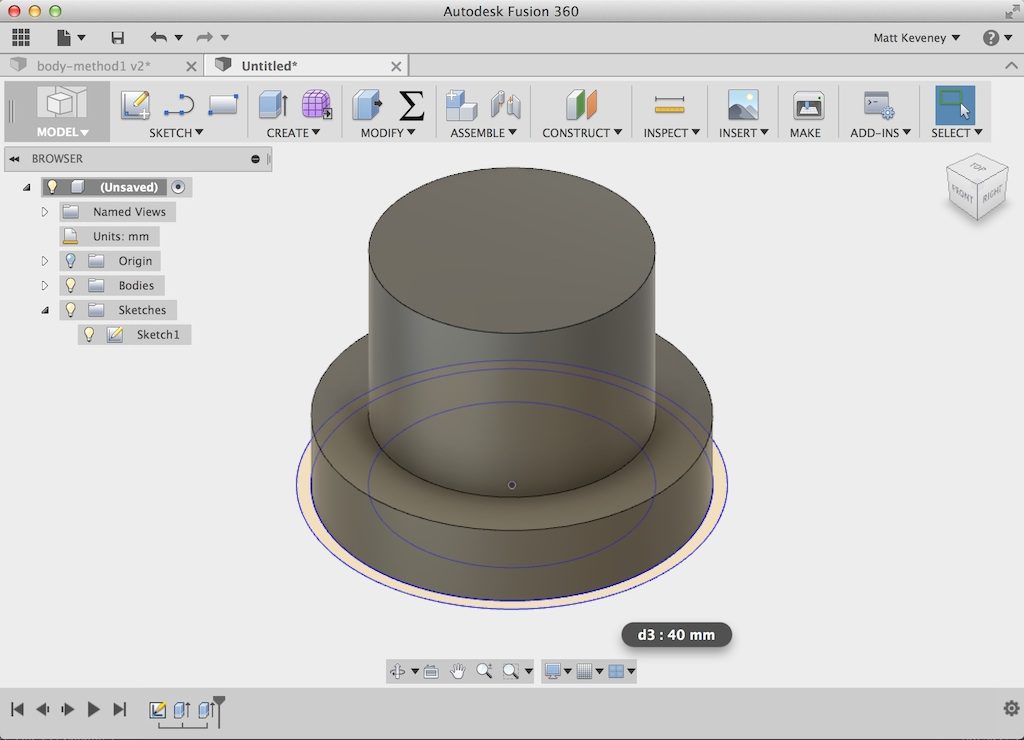

Next make three extrusions using the push-pull tool. The first extrusion is the innermost portion of the stopper.

Fusion 360 automatically hides the sketch after this operation, so we need to unhide it again (click the light bulb in the browser). Then select the next profile outward and pull to the level of the stopper below the gasket.

Finally select the outermost profile and pull to the depth of the outer section.

I like this technique a bit better, since the three diametral dimensions can be viewed together and edited just by opening the sketch. We still have to go hunting to find or change the extrusion heights. I should note however that we can make this hunting somewhat easier by renaming the operations (right click in the operation history). This helps with the first method as well.

Stopper body, method 3

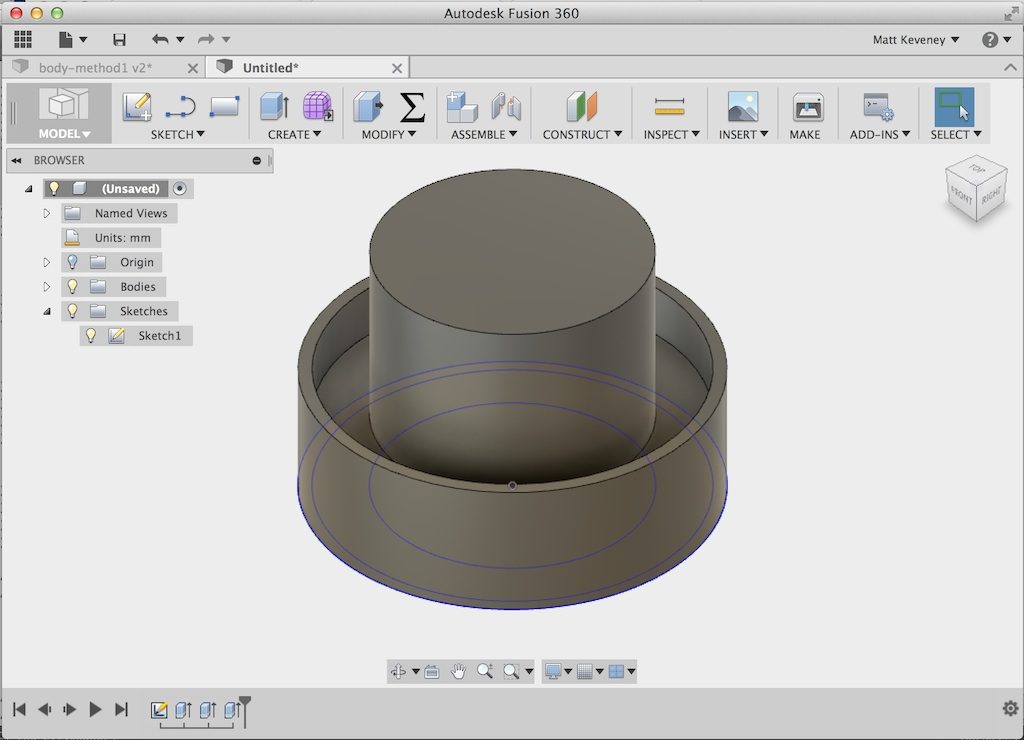

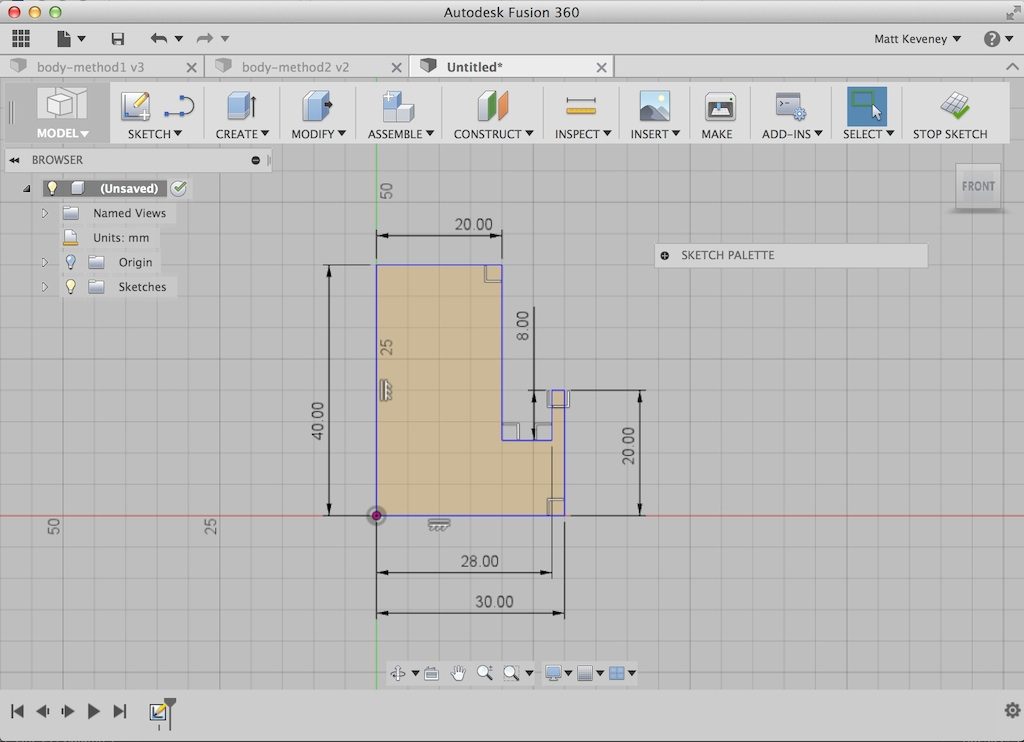

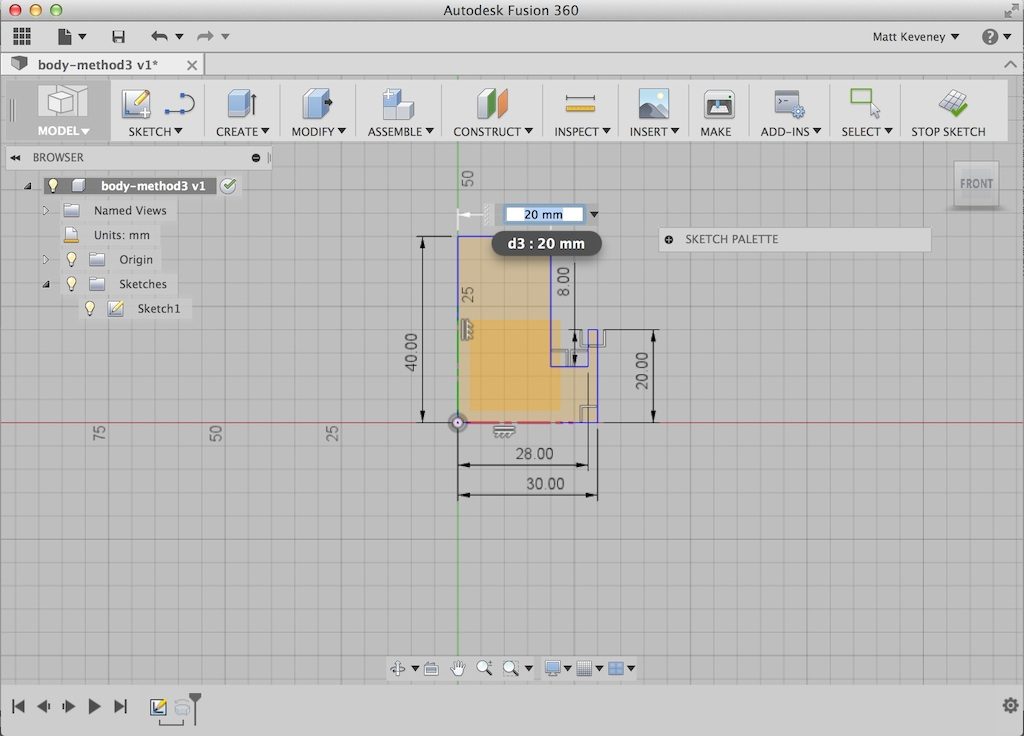

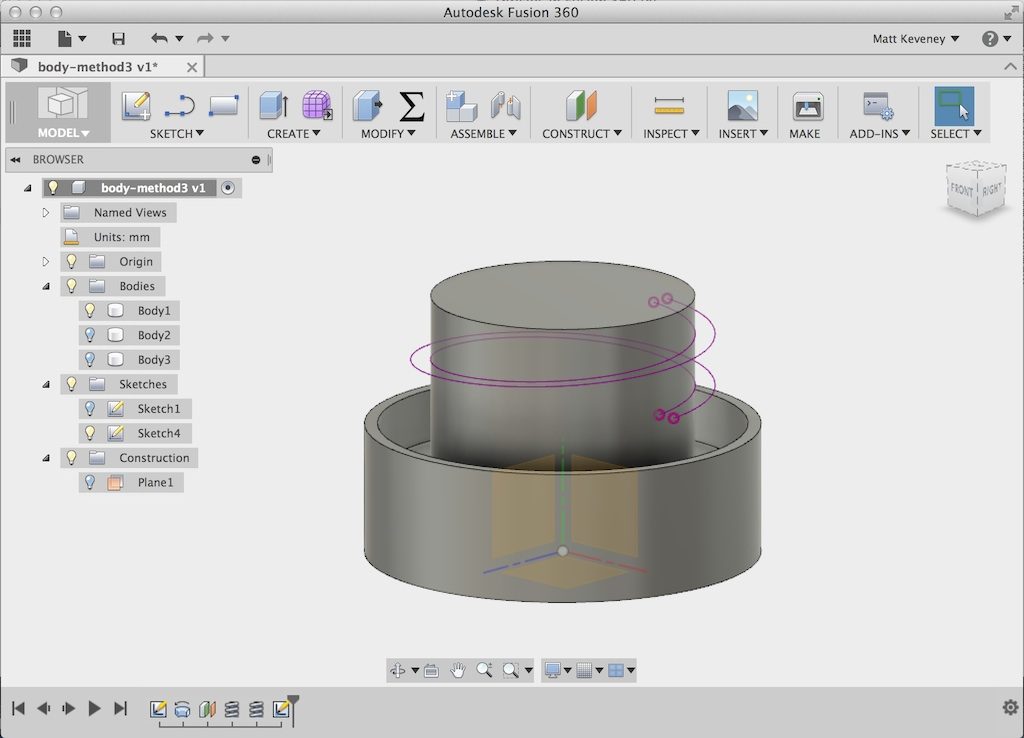

The final technique uses a single sketch in the XY plane which describes a radial cross section.

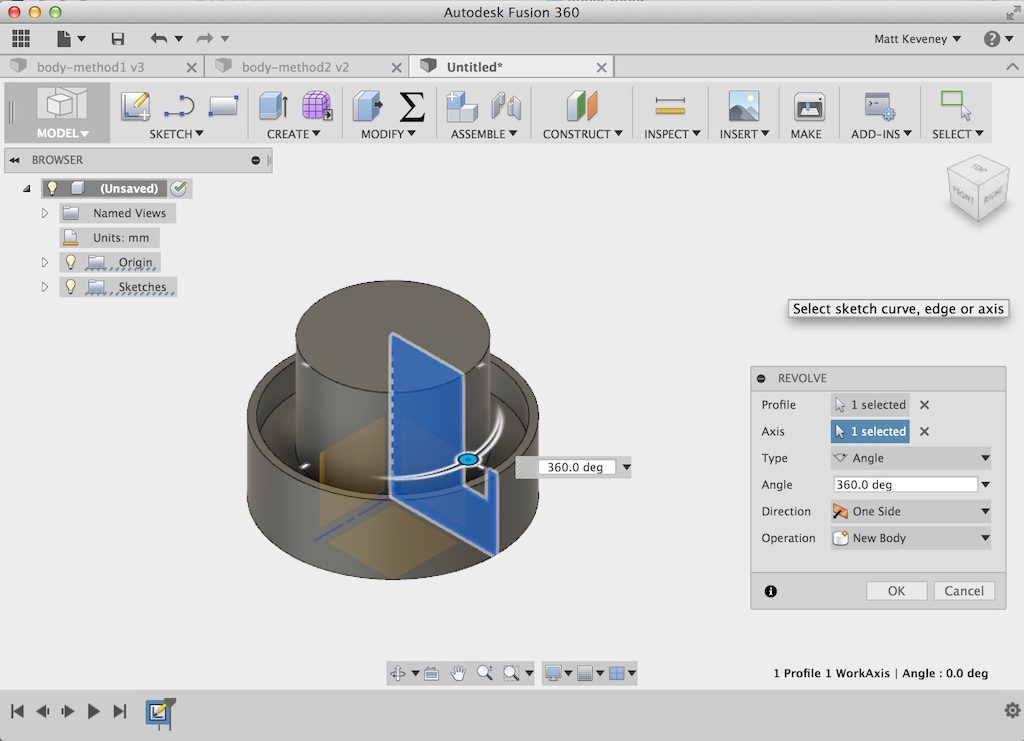

Then we create the solid with a single revolve operation.

While this might seem the most abstract of the techniques, it’s my favorite since all the dimensions I might want to change are located in a single sketch. I’ll use this version in the remainder of the article.

The threads

Now for those threads I keep promising. We’re going to create a profile and sweep it along a helical path.

Unfortunately Fusion 360 doesn’t seem to have convenient way to draw a helix. My first thought was to write a Python macro, but that’s probably because I’m a software engineer and If you own a hammer, every problem looks like a nail.

So, I spent a bit of time exploring other options and discovered the coil tool. This is obviously handy for modeling springs, but we’ll use it just to create our helical path and then hide the coil forever after. It turns out we actually need two parallel helices; the second serves as a rail to guide our sweep operation. Without the rail, the profile may twist while it sweeps along the path.

But before we start, we want our coil to have the same diameter as the inside portion of our stopper, so let’s go back into the stopper sketch and give that dimension a more meaningful name. First we open the sketch and double-click the dimension.

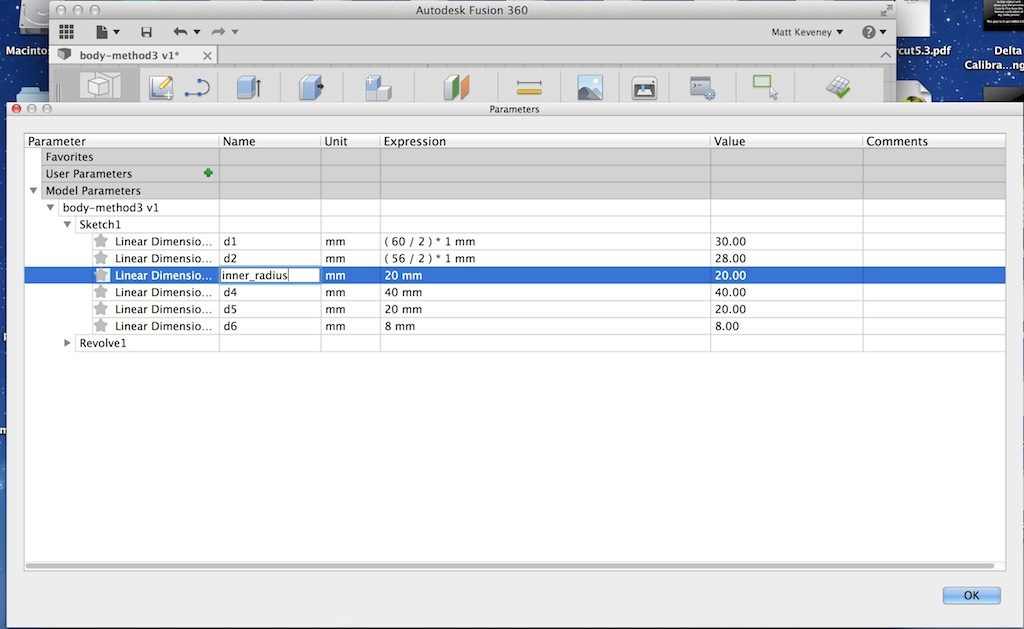

We see that it’s labeled d3. Then open the change parameters dialog, browse to dimension d3, and rename it inner_radius.

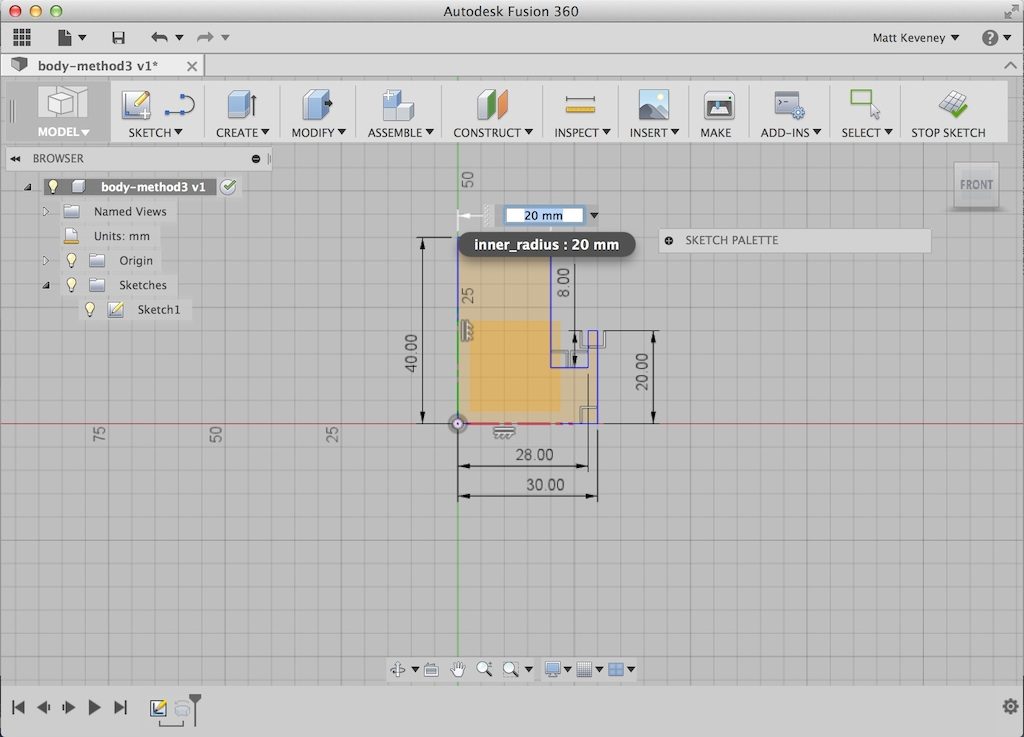

Now, if we double-click the dimension in the sketch we see that it has been renamed.

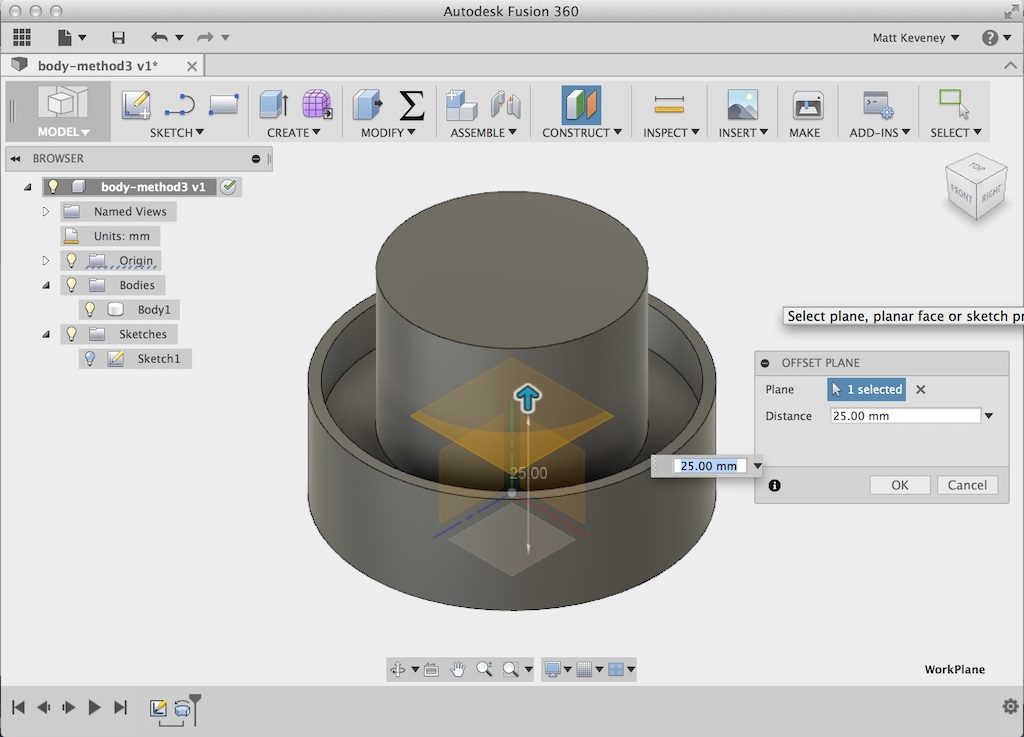

Create a new work plane, parallel to the XZ plane but offset upward to the lower extent of our threads (25mm).

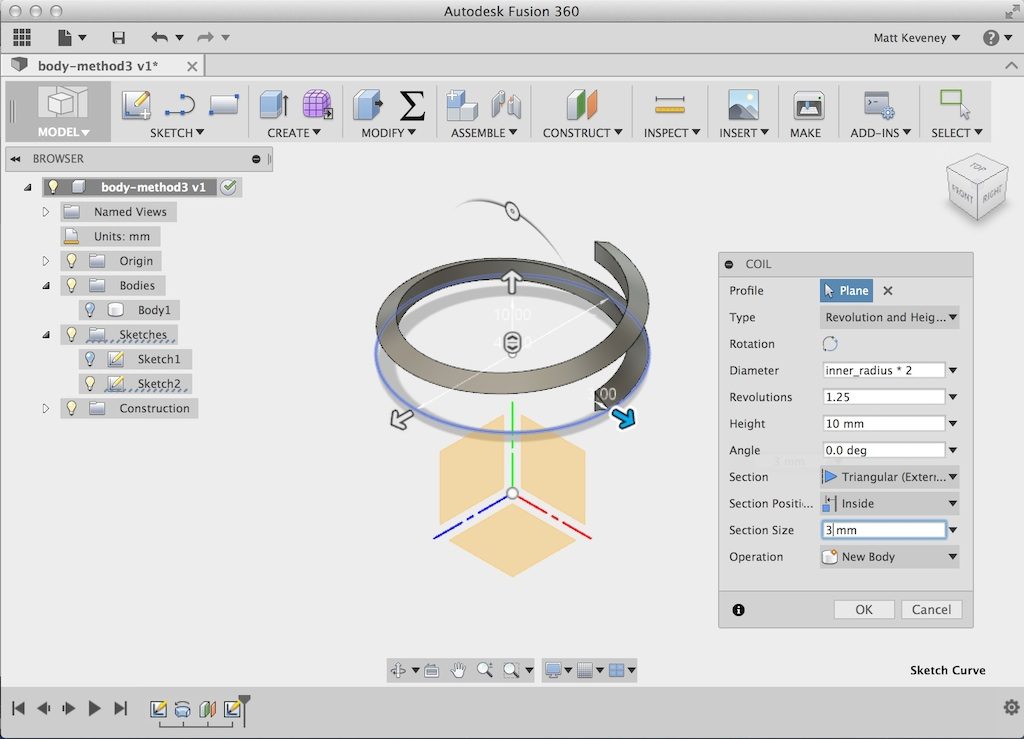

Hide the stopper body for now, just to get it out of the way. Then create the coil on the work plane we just added, centered at the origin. Use a triangular section, positioned on the inside of of our specified diameter, with the remaining settings as shown.

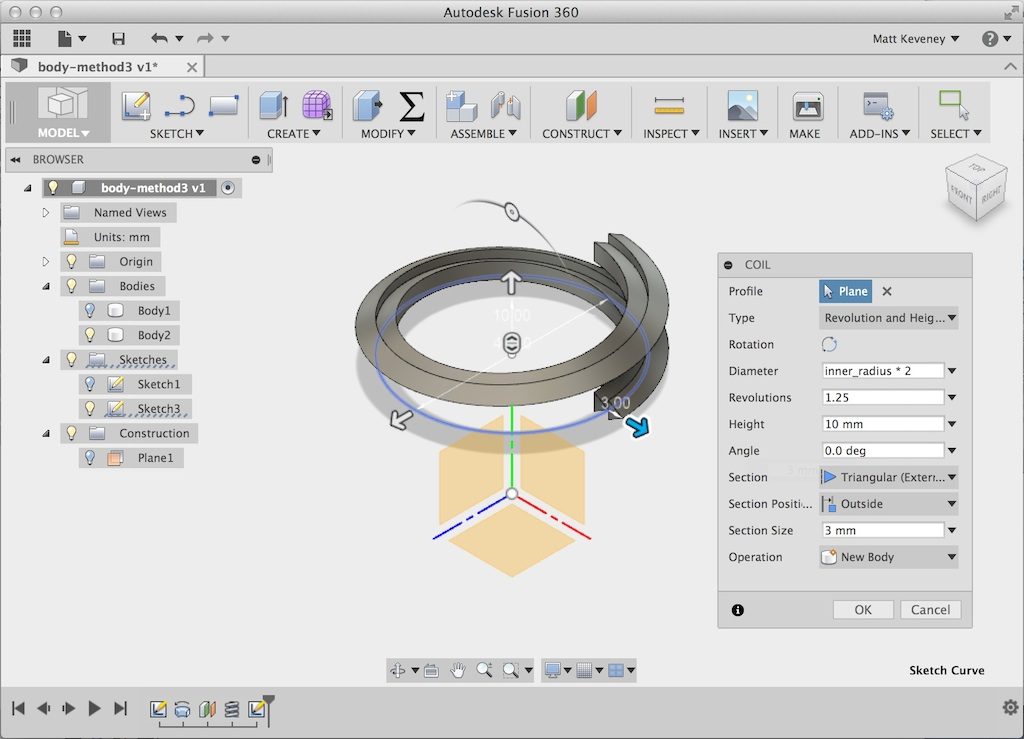

Note that the diameter is set to inner_radius * 2. Now, if we modify the dimension in the original sketch, the coil will automatically adjust to match. Unhide the construction plane, and create another coil identical to the first, except position this one to the outside.

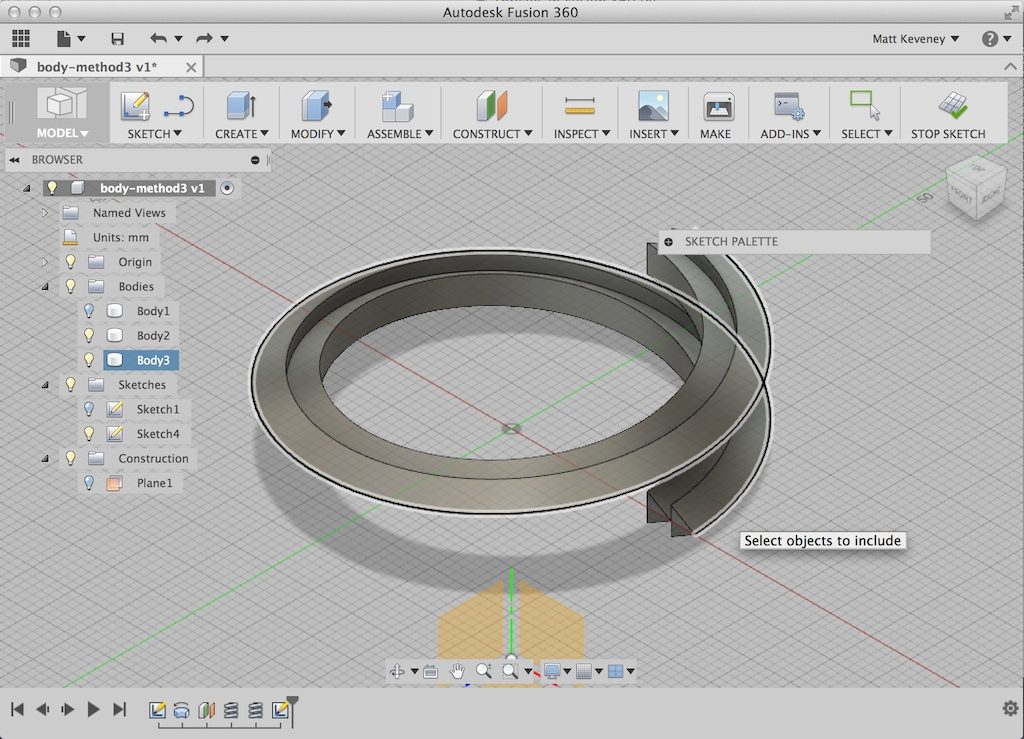

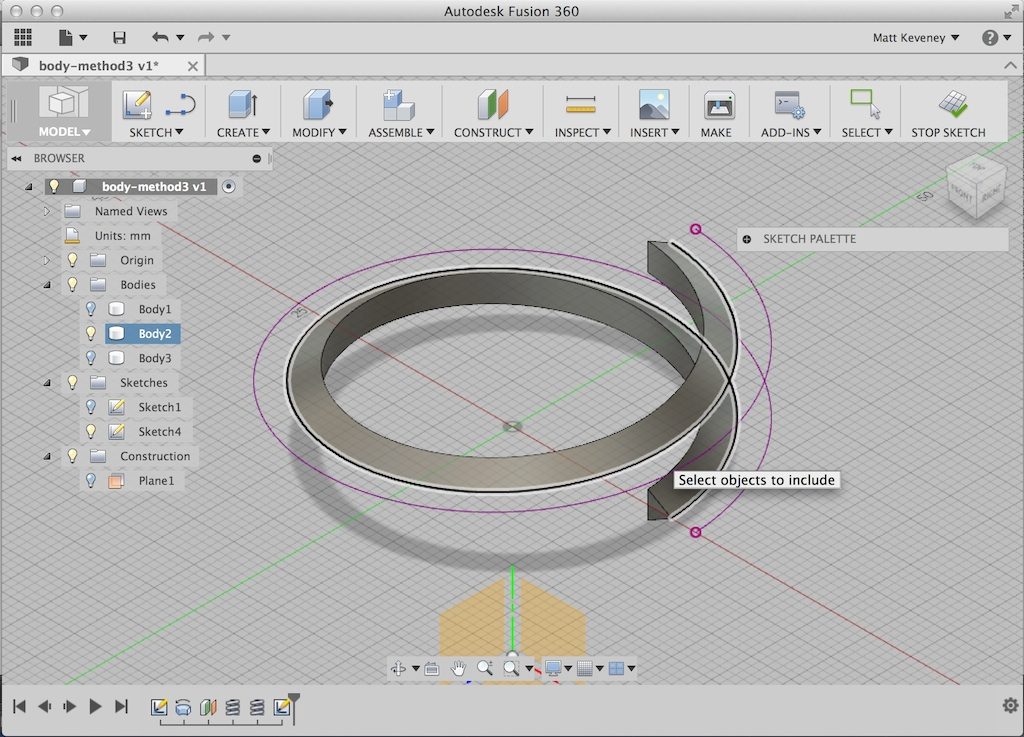

Select the work plane again (unhide first, if necessary) and create a sketch on it. Click the home button to get a perspective view, and select Sketch > Project/include > Include 3D geometry. Now click the outer edge of the outer coil. You’ll see a purple line appear.

Hide the outer coil, and select the outer edge of the inner coil. Another purple line appears. Hide the inner coil.

Whew! All that guff was just to produce those purple helices. Note that even though the curves are hovering over the sketch plane, they still belong to that sketch. Close the sketch and unhide the stopper body so you can see how these curves look in context.

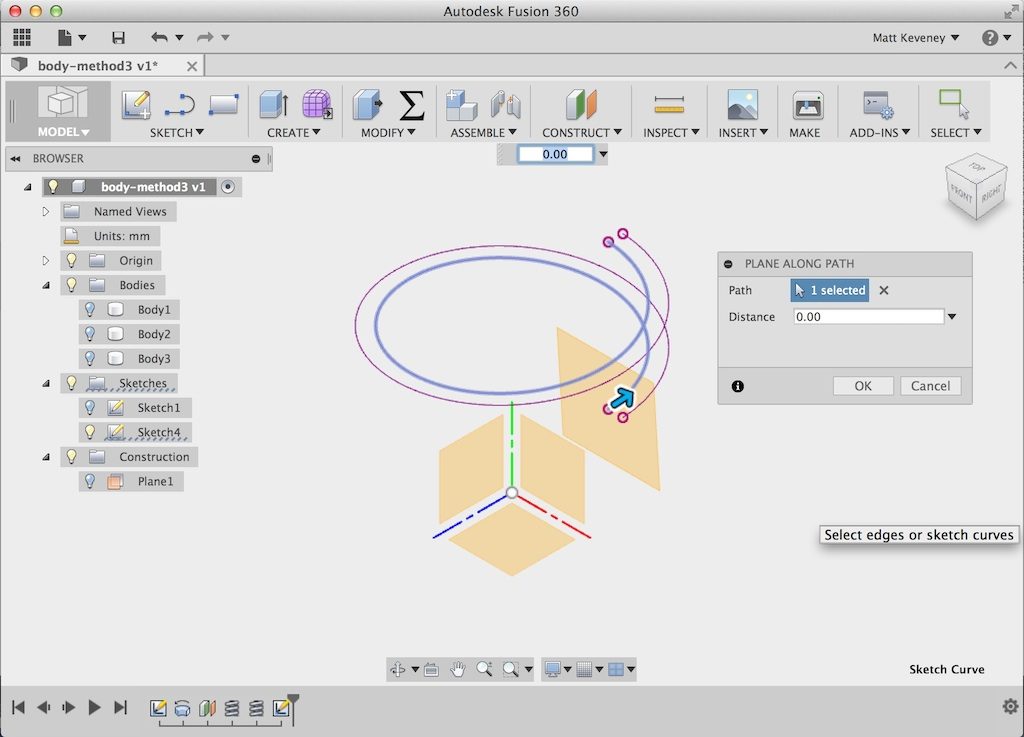

Hide the stopper body again, select the inner helix and create a construction plane along the path. Drag the plane to snap to the lower end of the helix, and finish the operation.

Drag the view around a bit, and notice that the plane is not quite vertical but is perpendicular to the helix. This is important for the upcoming sweep operation.

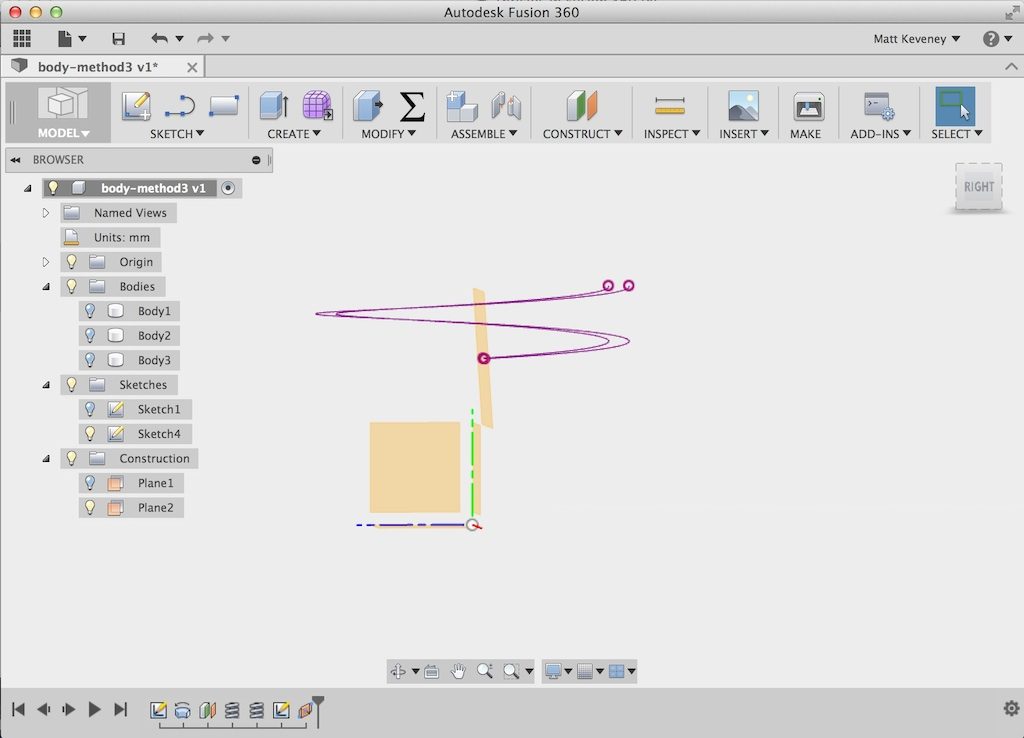

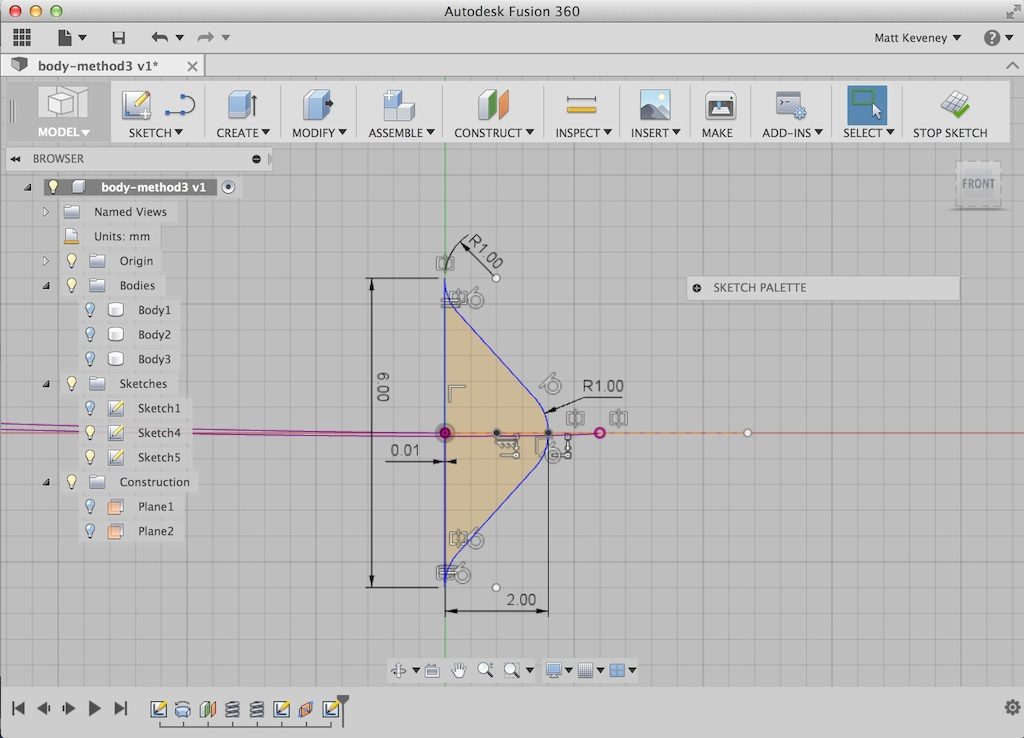

Select that plane and create a sketch. Then draw the thread profile and close the sketch.

The sharp eyed will notice that the left vertical line in my profile is offset slightly left of center. This forces that edge of the profile to end up inside the inner cylinder. Otherwise, only the center point of this edge would actually touch the cylinder, since the entire plane upon which it is drawn is tilted slightly from vertical. Offsetting slightly inward avoids intersection problems when we later join the sweep to the stopper body.

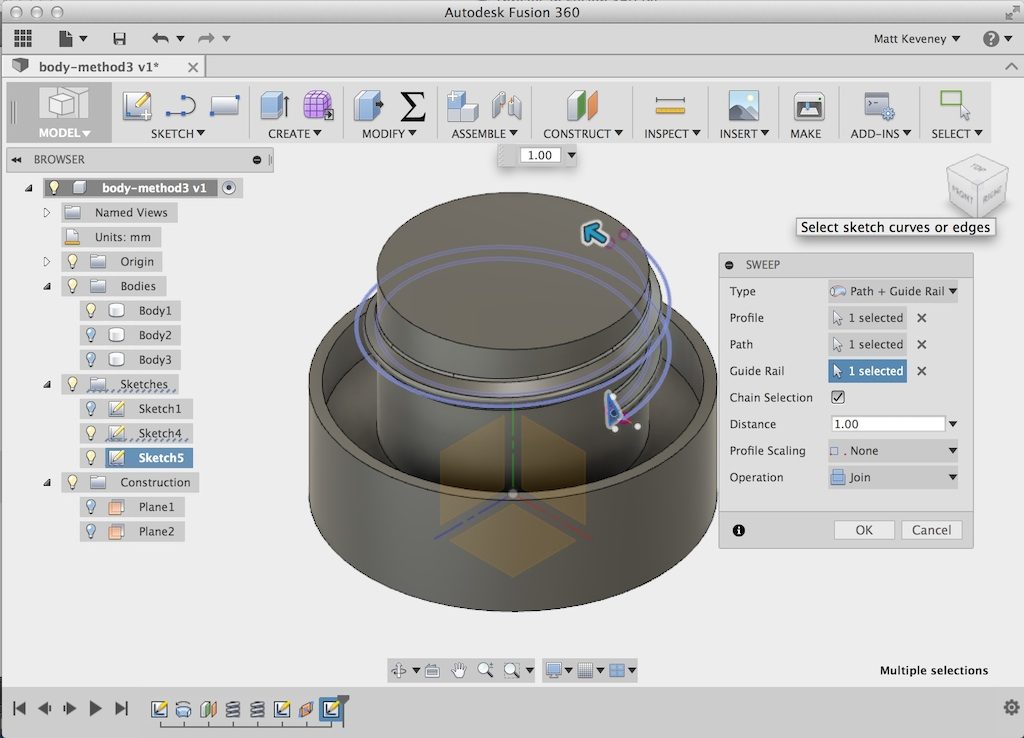

Now, finally, unhide the stopper body and select the sweep tool. Select type: Path + Guide Rail, then choose the new sketch profile, the inner helix as the path, and the outer helix as the rail. Turn profile scaling off, unhide the stopper blank, and select operation join.

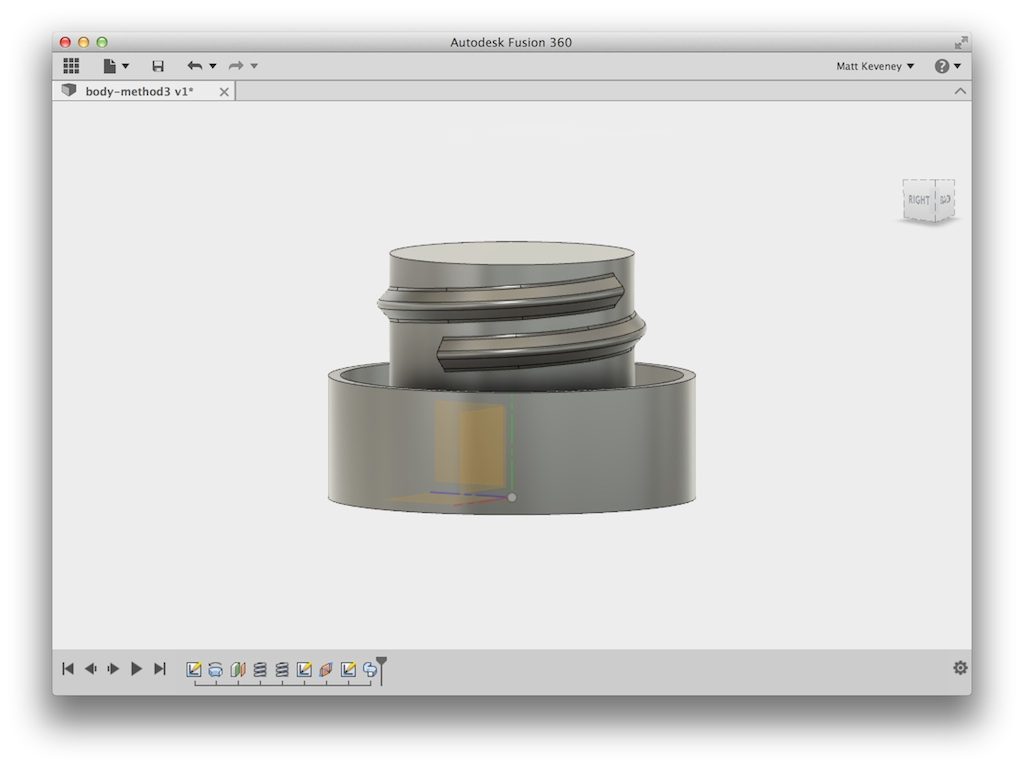

We’ve added our custom thread!

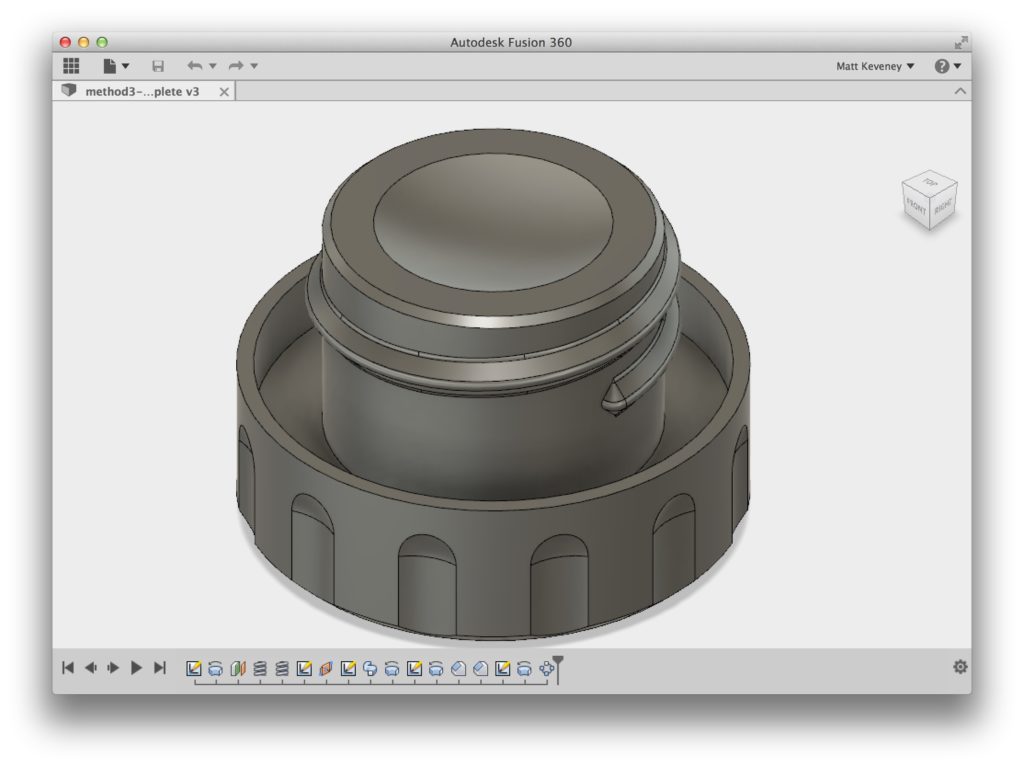

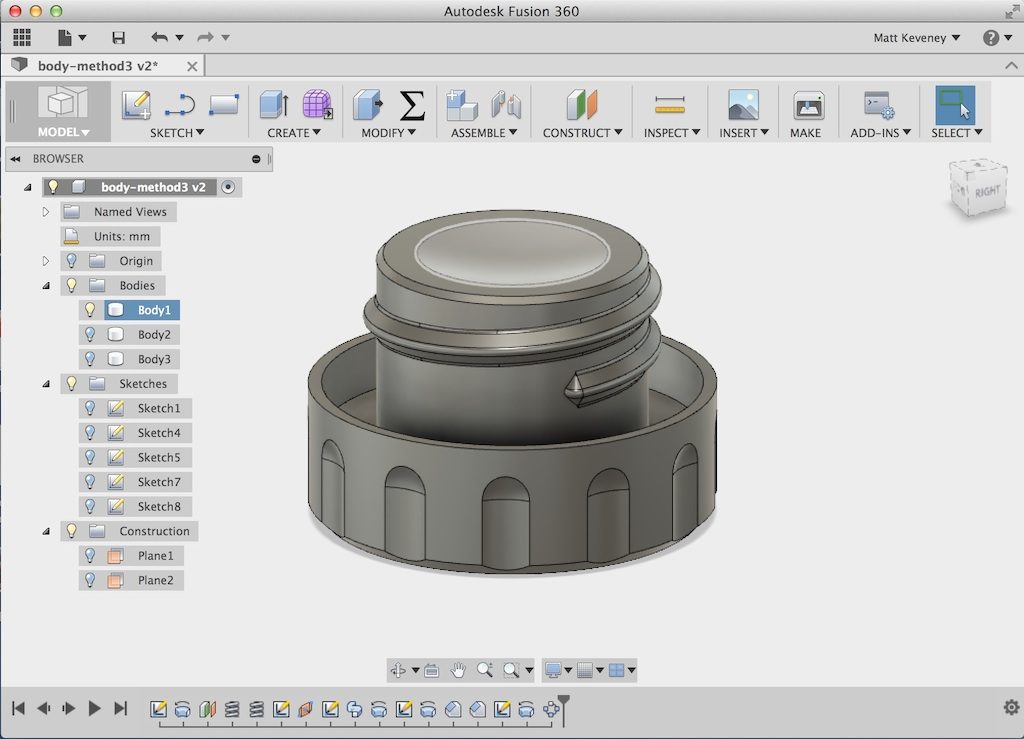

Here’s the model after a few more cosmetic operations.

Of course I know you wouldn’t believe a word of it unless I printed one out, so here you go.

I hope you’ve enjoyed this article. Please leave your feedback below, including any other modeling questions you might have. Does anyone have any interest in a modeling class for 3D printing? If so, give me some ideas for what it should include!

-Matt

Just two guests tonight. Maybe holidays that happen on game 7 of a Warriors series aren’t the best choice for meetings!

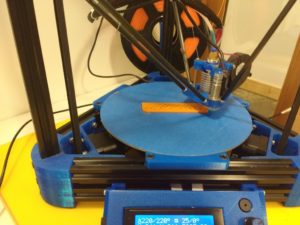

But we had fun anyway. Terry and Claire were back with their Prusa i3 kit. After a bit more tweaking and leveling we did manage to print a test block, but our success was marred by a slight leak in the nozzle. I sent them off with instructions for cleanup and repair, so I think we can expect cool results very soon.

We had a great turnout at tonight’s 3D print meeting!

Welcome newcomers: Alex, Kevan, Efrem, Nate, Terry and Claire (did I miss anyone?), along with returning guests Enric and Jill.

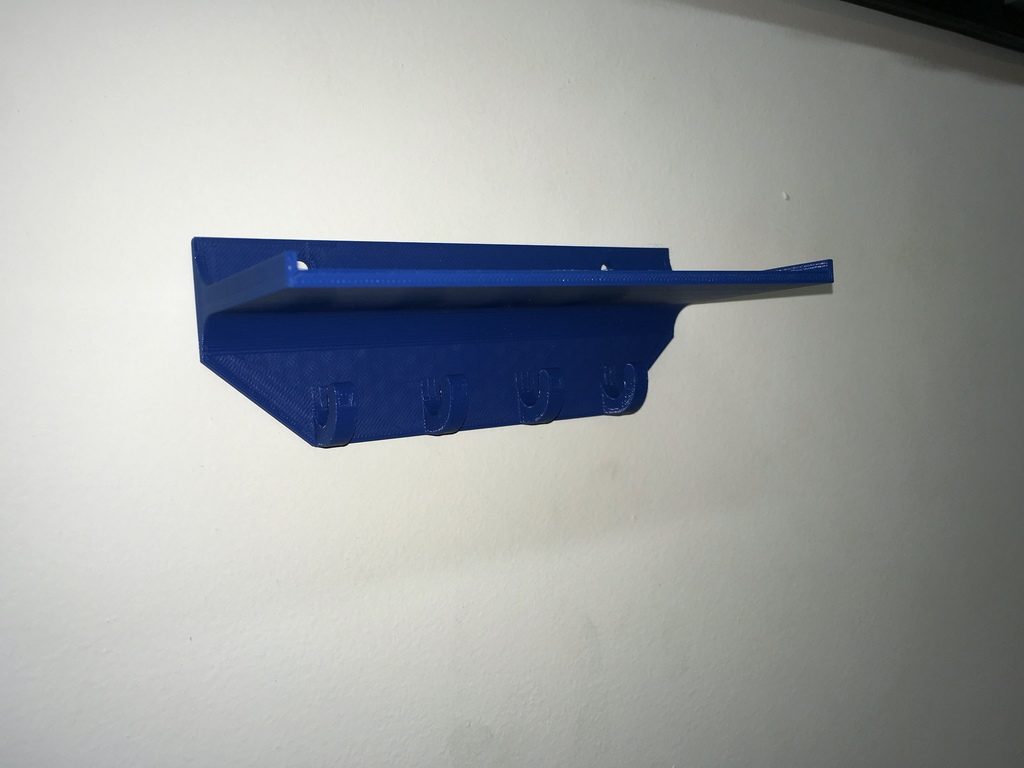

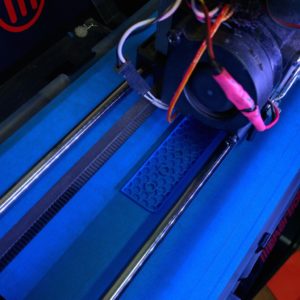

It was a busy night with a lot happening. We demonstrated a print on the Replicator II, printing a key-holder Nate found on Thingiverse. I brought my delta and demonstrated a simple print on it as well, to show how the workflow differs for the open-source toolchain.

Next we discussed design a bit using Jill’s water bottle stopper as an example to model in Fusion360. That’s a great example since there are so many ways to do it. Watch for a future post on how to model the thread.

Enric brought along a few of his electronic-project enclosures for show-and-tell. He’s also been doing some interesting experiments with light-pipes for wearable-electronics.

The highlight for me was Terry and Claire’s new Prusa i3 printer! They got a very inexpensive kit from AliExpress for under $200!, and had just finished assembling when they brought it here. After a bit of testing and fiddling with wires we had it mostly working. Unfortunately it was getting a bit late so had to stop a few inches short of that exciting first print. I sent them off with a list of things to do, after extracting a solemn promise to send us pictures.

I was very impressed with the quality of the kit; and the price was better than you could do sourcing the individual components yourself. According to Terry, shipping was very fast. I got the impression the instructions were a bit on the thin side, but that’s what we’re here for.

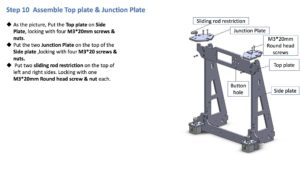

5/19/2016: After I wrote this, Terry was good enough to send me a copy of the digital instruction manual that came on an SD card with the kit. I must say, It looks a lot better than I expected:

Terry and Claire: we’d LOVE for you to write up a review of the kit and your experience building it. I always tell folks how easy it is, but the opinion of a power-geek like me simply can’t be trusted. If word gets out that normal well-adjusted folks like you can do it, maybe more would give it a try.

-Matt

A South Pointing Chariot is a vehicle carrying an indicator that always points South. As usual, there’s a good article on Wikipedia.

While the device was mentioned in a number of ancient Chinese texts, no design or construction details have survived. My model (like many others) assumes that a differential gear train was employed.

It’s been a fun project, but it’s a bit too difficult to assemble, and the wheels need work. watch this space for an updated version, including full CAD source files.

-Matt

Just two folks attended tonight’s 3D printer meeting; both were newcomers. Welcome Joe and Julio!

Both came armed with Fusion 3D models. I won’t divulge the details, in case they embody valuable trade secrets, but it was exciting to see such advanced preparation.

We did the usual walkthrough on the Replicator II. Joe had to leave early, but assures me he learned a few things. Julio stuck around to see his first part printed. We selected the simplest of three that he brought along. I suggested a few modifications to the other parts that would likely make printing more successful.

I brought my delta for demo purposes, and also brought my latest project for show & tell: my south-pointing chariot. Expect a more detailed writeup and perhaps a short video clip later. I’ll bring it to Thursday’s meeting too.

-Matt

We had another great turnout for the 3D print design meeting. Eight folks in all. Two newcomers, Jill and Arun (Welcome!); two veterans, Enric and Don; two special guests from MadeSolid, Lance (and another fellow who’s name I neglected to write down); and Sean and myself.

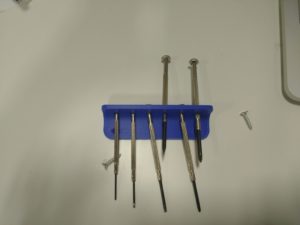

Sean showed off some of his cool work, and answered lots of questions as always. Jill and I walked through a simple Fusion 360 project: A small screwdriver rack for my tool-board.

I forgot to bring the screwdrivers along, and was afraid the holes might be a bit too tight. Sure enough, when I got back to my shop I found out they were. Just enlarged them a bit and reprinted on my own printer.

This only took about 20 minutes from a blank screen in Fusion 360 to starting the print (which took almost an hour). Designing something like this can be fun and easy once you get your feet wet with a modeling tool. Come to the next meeting and see how much fun it is!

-Matt

Last nights ‘3D print design’ meet up was attended by just two guests! Enric and Don. Nonetheless, we had a very productive session.

Don was a complete newcomer and simply wanted an introduction to it all. I printed a bevel gear and walked him through the process. The gear was created by a Fusion360 macro I’ve been working on… I’ll show it off at an upcoming open-house when it’s done.

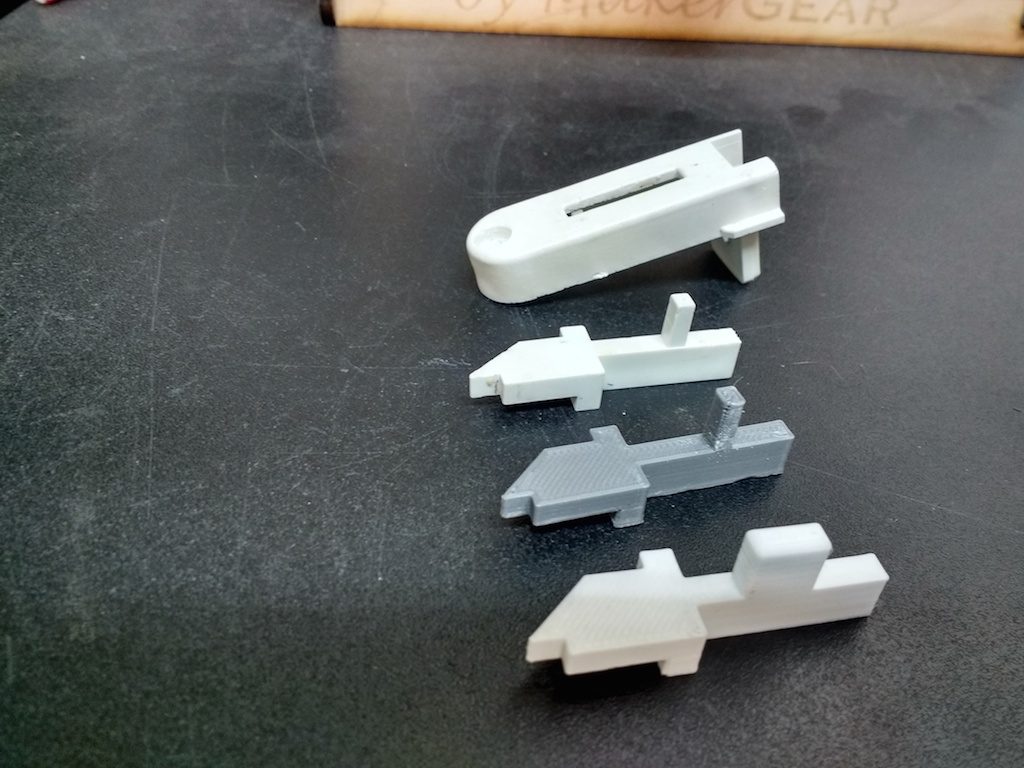

Enric had a very interesting project that really shows off 3D printing’s potential for solving everyday problems. Several of the windows latches in his house have broken. Unfortunately the parts aren’t manufactured anymore.

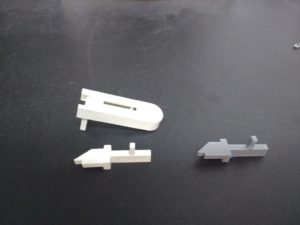

He found one that is still intact, removed it from his window and brought it along. After some careful measurements (Enric brought his calipers too), we were able to create an accurate model in Fusion360 and print it.

The part fit on the very first try (the gray part in the photos). I feared that the small projection used to slide the latch might be a bit weak, and upon examination we found that the housing would allow us to simply enlarge that portion. It gave us a good excuse to revise our model and reprint, showing off the benefits of a parametric modeler to best advantage. We switched to a better color while we were at it. The new piece seems to fit just as well as the first.

But, does it work? It seemed okay in the lab, but we’ll have to wait for Enric’s installation report! Enric?

Here’s the Fusion360 model if you want to have a closer look.

Monday was the first meeting of the ‘3D printing Tinker Group.’ I think it was a roaring success.

I brought my delta and had it running for demonstrations, and we had seven guests who brought a total of 3 printers along.

James brought his in-progress delta, which is almost ready to go. His belts were installed funny, a glance at mine cleared that up; but he decided to reinstall the belts later when he’s comfortably sitting at his own tool bench. He was also annoyed by power-supply noise and is already thinking about a replacement. I think we can look forward to first print very soon. James, please keep us posted! (I’ll send you my switch plate STL separately).

Rosalind, Natalie and Susie brought the Replicator II that Susie’s students use at school. A slightly warped bed seemed to be the culprit here; simply flipping it over and a bit of practice leveling got it going. Their Rep II has a small fan duct that embraces the nozzle. They reported that this duct occasionally slams into the work, either dislodging the work or breaking the duct itself. I recommended simply removing it if it causes trouble again… our Rep II has no such duct, and the fan still cools the work just fine. Susie reported a lot of frustration working with Makerbot support <sigh>. Sorry to hear about that. Please spread the word that we’re here to help.

Enric brought his nice Ultimaker. A walkthrough on bed leveling was all it took to print out a nice high-resolution print. Enric is particularly interested in printing custom cases for his Arduino projects, so if you have any info he’d appreciate it. Enric, I searched Thingiverse for ‘customizable box’ and these two jumped out. Perhaps they’ll give you some ideas.

http://www.thingiverse.com/thing:189264

http://www.thingiverse.com/thing:189264

Two guests, Andrew and Noah were there to learn. We walked through a simple print job on my delta to demonstrate the typical print sequence; fortunately(?) I got a chance to demonstrate how to cancel and reprint when the first layer doesn’t stick!

I had a great time and went away with renewed enthusiasm for my new role as steward.

These devices can be very fussy and unreliable even when everything is working properly. There’s no such thing as ‘plug and play’ no matter what marketing BS you may have read. If you’re new to it all, it’s tough to tell the difference between a device malfunction or simple unfamiliarity with the process. Please spread the word that we’ll be happy to help anyone get his/her printer going.

The ‘tinker group’ meetings specifically target these issues, but feel free to bring your printer to any AMT 3D print meetup. We’ll see what we can do.

-Matt Keveney