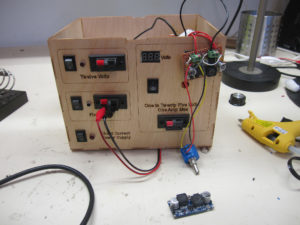

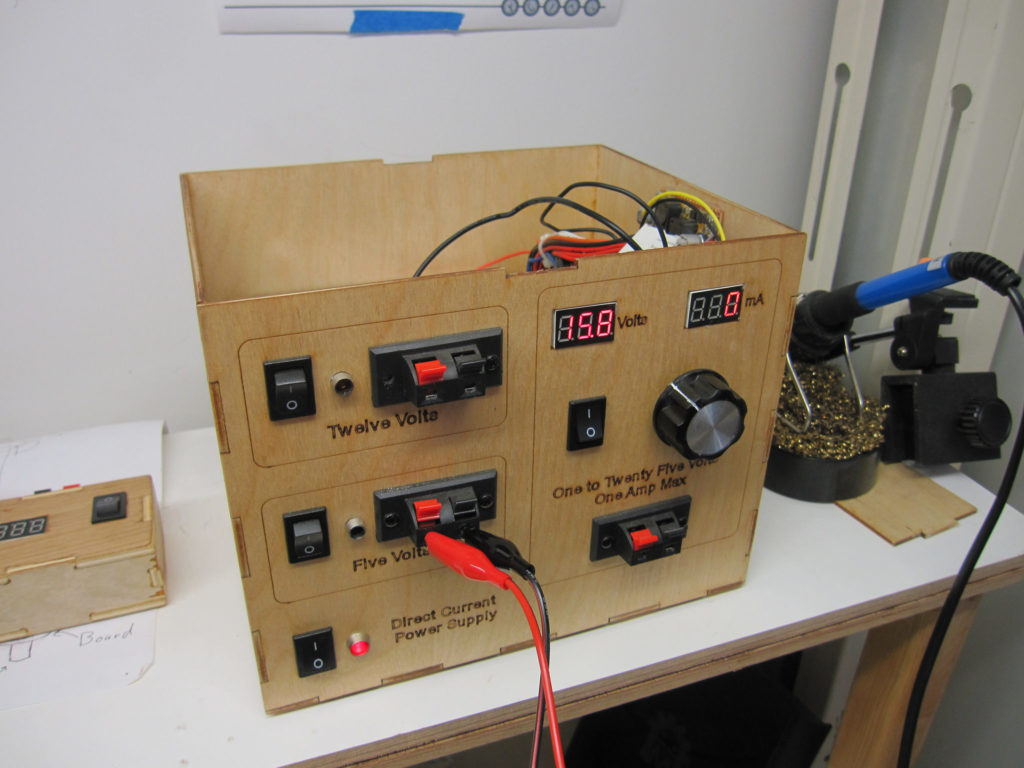

The custom power supply in Electronics has a few basic components. An old Dell PC power supply, a bunch of wires and connectors and a DC-DC buck/boost converter module to give us variable output. That module was no longer working so I swapped it out for a new one. The culprit for the module dying? No idea. Could have been a lot of things and it’s going to stay a mystery.

When installing the new module I had a 50-50 chance of getting the wires right for the direction the knob turned to change the voltage and this time, the odds were against me. After prying the old module’s hot glued body off the side and desoldering and connecting up the new module it turns out I put the control wires in backwards and you turned it counterclockwise to increase. Thought about leaving it that way for the comedy factor and decided against that. A little wire swapping and lo! the knob works as it should.

The new module seems to be working just fine. I haven’t priced out new DC-DC buck/boost modules in awhile and it turns they are now even lower in cost, under $2 each. I ordered three as spares just to make sure for next time.

Edgy-Cam is a Raspberry Pi with a camera module and connected to a thermal receipt printer. Using the Canny Edge Detection algorithm, photos are taken with the camera, processed and turned into hand drawnish monochrome image that is printed out on the thermal printer. Like other instant cameras, but with some serious image processing going on. Every processed image is a monochrome 512×384 and given a unique filename and saved on the Raspberry Pi. Images can be retrieved later if people are interested.

Edgy-Cam is a Raspberry Pi with a camera module and connected to a thermal receipt printer. Using the Canny Edge Detection algorithm, photos are taken with the camera, processed and turned into hand drawnish monochrome image that is printed out on the thermal printer. Like other instant cameras, but with some serious image processing going on. Every processed image is a monochrome 512×384 and given a unique filename and saved on the Raspberry Pi. Images can be retrieved later if people are interested. The case is made out of 1/4″ baltic birch plywood and was CNC cut at AMT. The black inlay is tolex, a vinyl like material and this is the same pattern as found on Marshall guitar amplifiers. After cutting and assembly, the case had the edges rounded over on the AMT router table. All case assembly, sanding and gluing was done in the AMT woodshop.

The case is made out of 1/4″ baltic birch plywood and was CNC cut at AMT. The black inlay is tolex, a vinyl like material and this is the same pattern as found on Marshall guitar amplifiers. After cutting and assembly, the case had the edges rounded over on the AMT router table. All case assembly, sanding and gluing was done in the AMT woodshop.