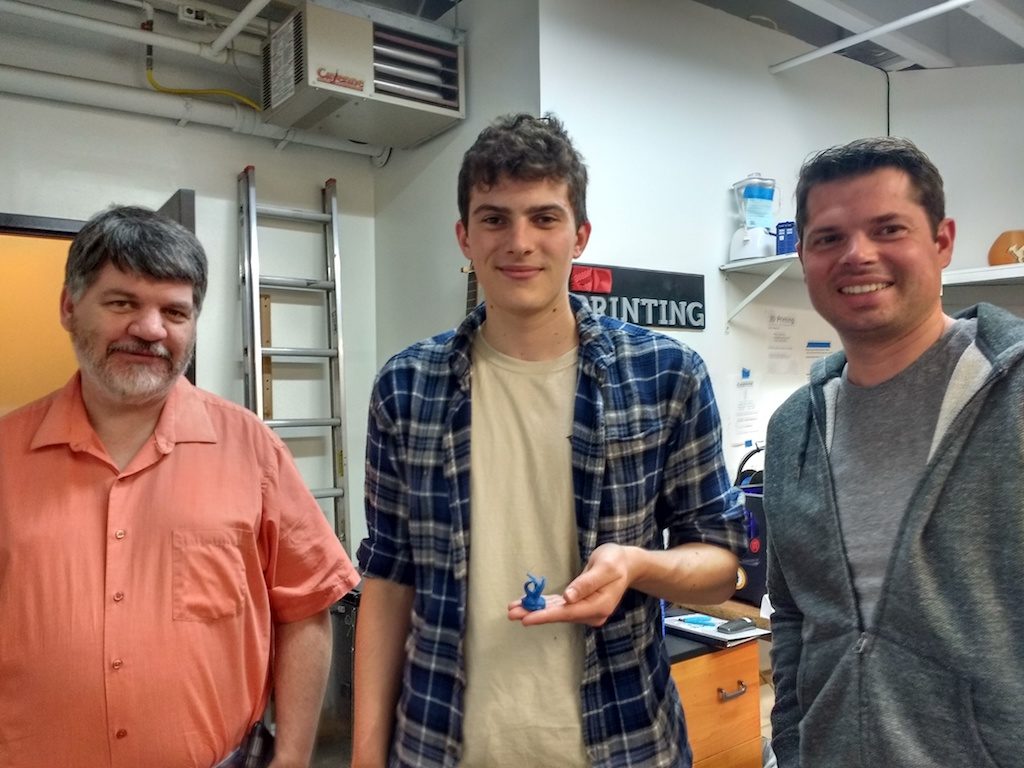

At last night’s hangout we had four guests. Two newcomers: Max and Klario; veteran Grant was there, and newcomer Mark, an experienced 3D print user wondering what AMT is all about. I neglected to write a blog post for our last 3d printing hangout (on 10/17/2016), so in this post I cover a few things from that meeting as well.

A former member (We miss you, Will, come back!) donated a 3Doodler pen (the3doodler.com) that has sat unused for months. A few weeks back, Grant asked about methods to fasten 3D printed parts together and I suggested he give the 3Doodler a try. I don’t think it’s really designed for the purpose, but nobody else was using it, so why not?

Last meeting, he reported his results: Spotty, unfortunately, but mostly because the pen seemed to be having some mechanical problems. But the idea still seemed to have merit…

So, as all proper inventors must, Grant has decided to make a better one. He’s hacking together a glue-gun and a 3D printer hot-end. I’m dying to see the result, and I think we should all gang up on Grant and force him to write a blog post on his progress!

We did the usual printer walk-through last night. We printed a jackknife-style keyring and a weird alien chess piece as samples. We also talked briefly about design, but most of our guests were already somewhat familiar with design processes.

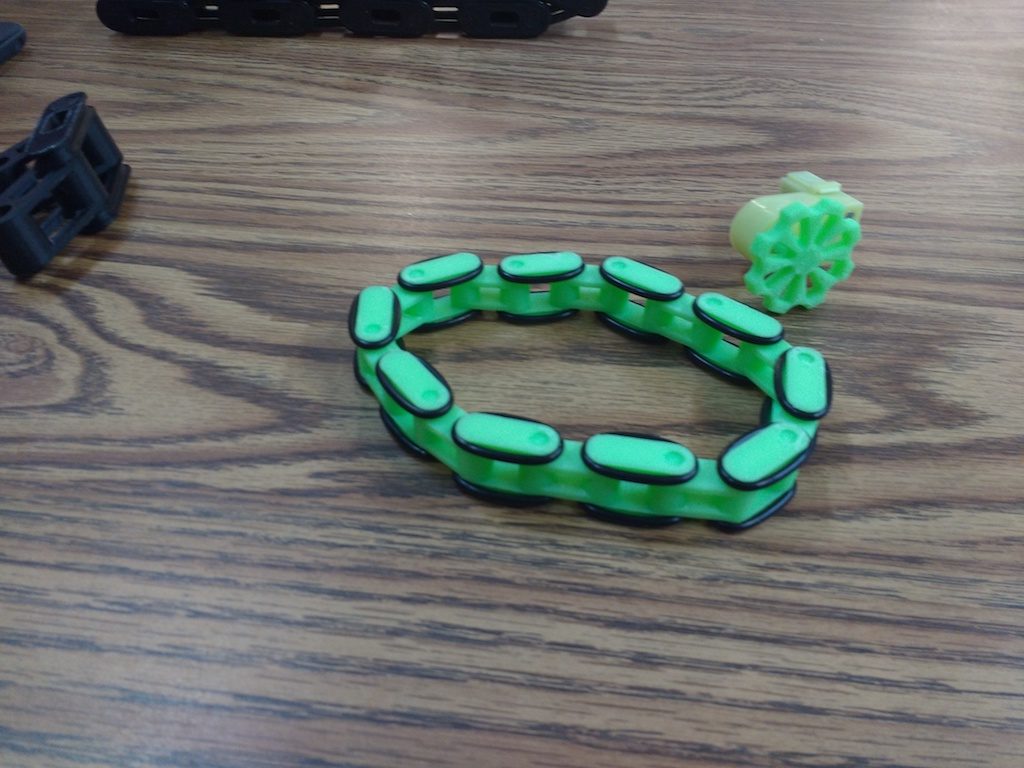

As things were drawing to a close, Mark just casually mentioned that he had a few samples of his work in his car, if we were interested in having a look… I only wish he’d mentioned them sooner! Mark has some really cool robot drive systems, almost entirely 3D printed! I immediately dragged him upstairs to show Ray, who I knew would be interested.

Mark’s tank tread sections use O-rings for traction, and press-fit together with a very satisfying snap. They’re held together by friction, naturally augmented by the ridges the 3D printing process produces. He has designed a few test pieces to get his hole sizes just right.

Mark is thinking about joining AMT; I sure hope he does. In any case, I’ve asked (nay, demanded) that he keep returning to share his progress. Please know that our 3D printing hangouts are open to everyone; not just members. Whether you’re completely new to it, or an experienced veteran like Mark, we’d love for you to join us and share in the fun!